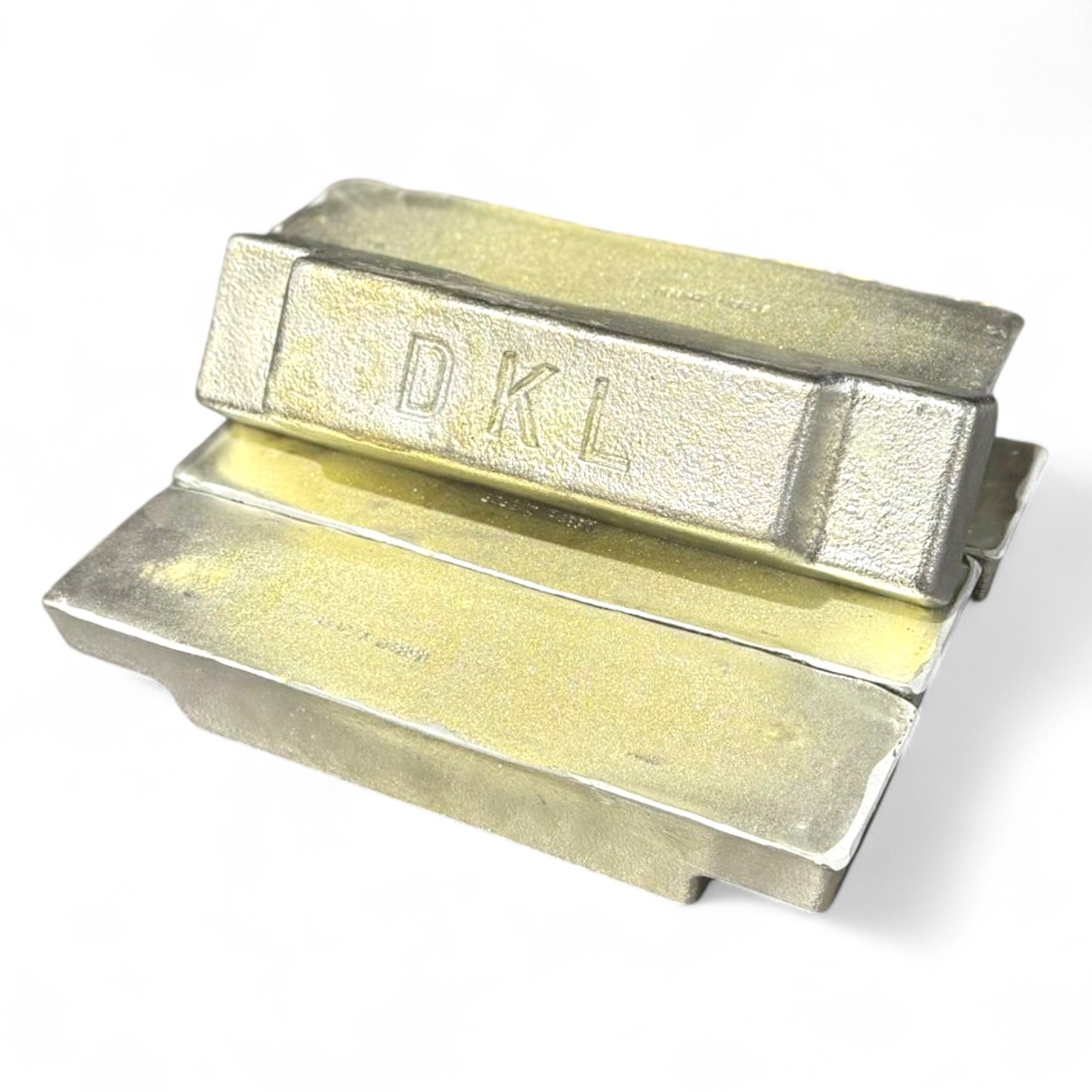

BS3332/3 White Metal Bearing Alloy

Specialised High-Tin Bearing Alloy

BS3332/3 white metal bearing alloy is a developed high-tin bearing alloy designed for advanced performance requirements where enhanced mechanical strength, wear resistance, and corrosion protection are critical. Featuring a high tin base with controlled additions of lead, antimony, and copper. This alloy offers properties for specialised industrial applications.

Chemical Composition

| Element | Typical Range (%) |

|---|---|

| Tin (Sn) | 80.0 min |

| Lead (Pb) | 3.0 – 5.0 |

| Antimony (Sb) | 9.0 – 11.0 |

| Copper (Cu) | 4.0 – 6.0 |

| Zinc (Zn) | Max 0.005 |

| Iron (Fe) | Max 0.10 |

| Nickel (Ni) | None specified |

| Bismuth (Bi) | Max 0.05 |

| Cadmium (Cd) | Max 0.10 |

| Silver (Ag) | Max trace |

| Gold (Au) | Max trace |

| Arsenic (As) | Max 0.10 |

| Aluminium (Al) | Max 0.01 |

| Indium (In) | Max trace |

Key Benefits

- High tin content for superior wear resistance and mechanical performance

- Special alloying elements tailored for enhanced corrosion resistance and durability

- Suitably engineered for demanding industrial and heavy-duty bearing applications

Typical Applications

- Advanced engine or machinery bearings

- Specialised industrial components requiring high-performance white metal alloys

- Applications benefiting from enhanced corrosion and wear resistance

Note

This alloy is part of the BS3332 family and comes under the BS 3332:1987 standard. Please consult DKL Metals technical support for application suitability and availability.

Why Choose DKL Metals’ BS3332/3 White Metal Bearing?

DKL Metals supplies high-quality white metal bearing alloys with full traceability and quality assurance. Our expertise and UK-based manufacturing provide reliable supply and technical support for your specialised alloy requirements.

Learn More!