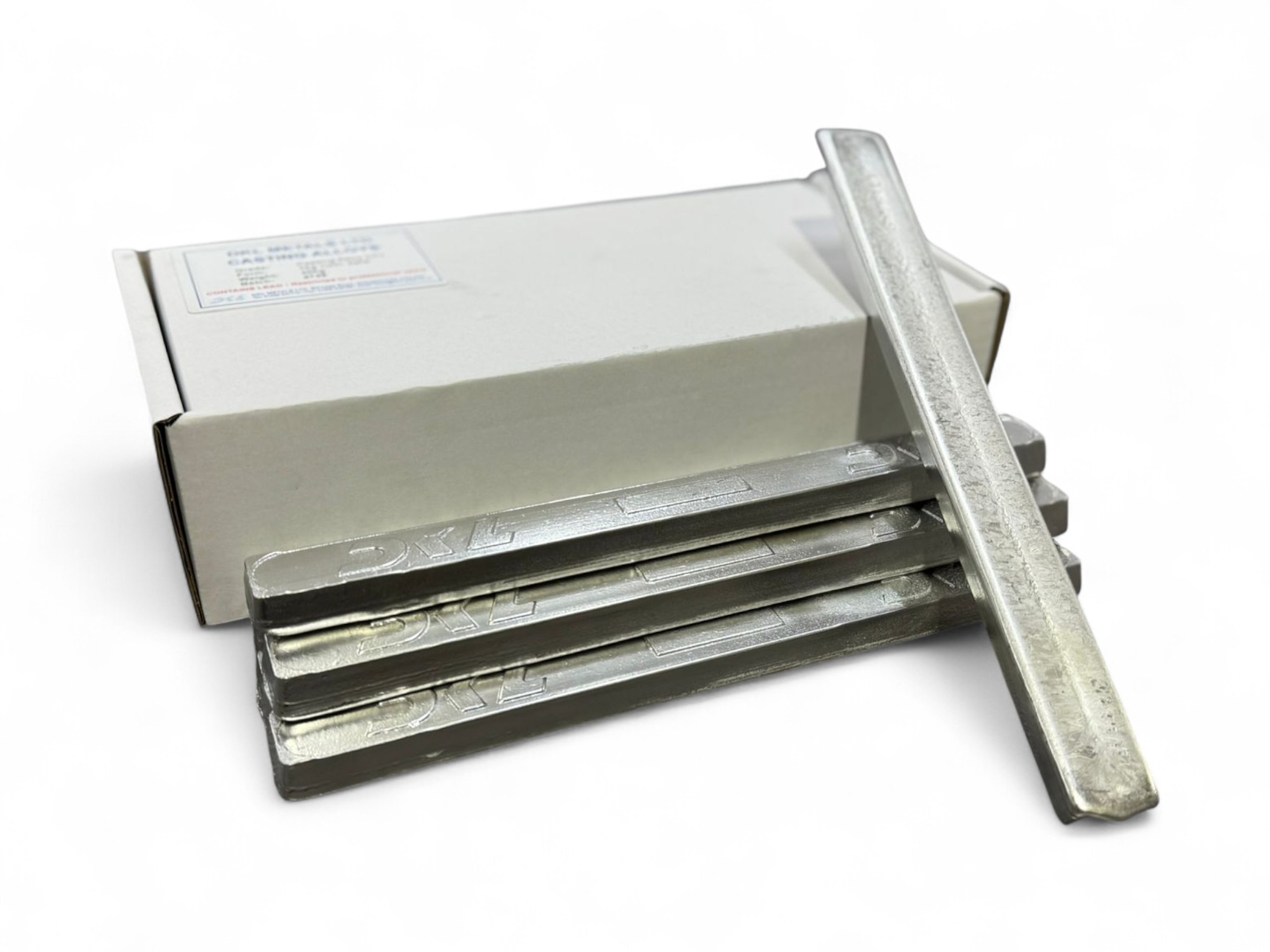

Casting Alloy CT1

High Grade Tin-Rich Alloy with Excellent Flow

Casting Alloy CT1 is a high-grade tin-rich alloy containing a small addition of lead, providing improved flow characteristics over traditional lead-free pewter. Known for its user-friendly casting properties, CT1 offers exceptional performance even at lower temperatures, giving a smooth, consistent metal flow and high-quality surface finish. Ideal for both hand casting and automatic casting setups, this alloy is favoured across jewellery, decorative, and precision casting sectors.

Technical Data & Properties

| Property | Value |

|---|---|

| Solidus | 185°C |

| Liquidus | 230°C |

| Density | 7.44 g/cc |

| Recommended Pouring Temperature | 260 – 310°C (approx.) |

| Alloy Type | Tin-rich alloy with small lead addition |

| Main Application | Jewellery, decorative and high-detail castings |

Key Benefits

- Improved flow compared to lead-free pewter, ideal for fine mould work

- Excellent surface finish with minimal porosity

- Easy to handle and cast – very user-friendly even for small batch work

- Suitable for hand casting or low-pressure casting systems

- High-quality finish suited to jewellery and ornamental products

Typical Applications

- Jewellery casting and fine decorative pieces

- Artistic and display reproductions

- Prototyping and design model work

- Custom, low-volume hand-cast components

Why Choose DKL Metals’ Casting Alloy CT1?

DKL Metals supplies Casting Alloy CT1 in tightly controlled batches to ensure reliable melting and flow properties. Our high-purity raw materials and alloying expertise guarantee smooth and repeatable casting performance. With precise composition and responsive UK support, CT1 remains a trusted choice for jewellers, modellers, and craft manufacturers seeking both quality and efficiency.

Learn More!

DKL – About Pewter & Casting Alloys