Grade G Solder

For Industrial and Electrical Applications

DKL Metals supplies Grade G solder, a trusted 40% tin lead alloy designed for industrial, electrical, and general-purpose soldering jobs. This alloy offers excellent wetting and flow characteristics combined with strong mechanical properties, making it ideal for manufacturing, repair, and metal fabrication processes requiring reliable solder joints with broad plastic range benefits.

Chemical Composition of Grade G Solder

| Element | Percentage (% by weight) |

|---|---|

| Tin (Sn) | 39.0 – 40.0 |

| Lead (Pb) | Balance |

| Antimony (Sb) | 0.40 max |

| Copper (Cu) | 0.08 max |

| Zinc (Zn) | 0.003 max |

| Iron (Fe) | 0.02 max |

| Nickel (Ni) | – |

| Bismuth (Bi) | 0.10 max |

| Cadmium (Cd) | 0.005 max |

| Silver (Ag) | – |

| Gold (Au) | – |

| Arsenic (As) | 0.03 max |

| Aluminium (Al) | 0.001 max |

| Indium (In) | – |

| Phosphorus (P) | – |

Key Features of Grade G Leaded Solder

- General Application and Plastic Range: A 40% tin, 60% lead alloy suitable for general-purpose hand soldering and torch soldering applications, possessing a broad plastic (semi-liquid) range between its solidus point (183°C) and liquidus point (238°C) that eases joint formation, filling of large gaps, and metal positioning.

- Wetting Performance: Exhibits good solder flow and wetting performance on copper, brass, and ferrous metals when used with appropriate (rosin or acid-based) fluxes for general electrical and metal fabrication applications.

- Mechanical Properties: Grade G solder provides moderate mechanical strength ideal for general industrial maintenance and repair applications. While it delivers reliable joint performance in typical operating conditions, it exhibits lower resistance to creep compared to newer solder alloys. This means it is best suited for applications without prolonged exposure to high temperatures or continuous mechanical stress.

- Industry Standards and Use: Conforms to historical and specific standards for lead-based solder alloys (e.g., ASTM B32 Sn40A, ISO 9453:2014 alloy n° 114) used in non-potable water plumbing, stained glass, and automotive radiator repair, but its use in new commercial electronics manufacturing is restricted in many regions due to the RoHS directive.

Typical Applications for Grade G Solder

Grade G solder alloy suits a wide range of applications including electrical component assembly, plumbing repairs, metalwork fabrication, and general industrial soldering tasks. Its higher tin content and plastic phase characteristics make it popular among manufacturers and maintenance engineers who require consistent, strong, and reliable solder joints.

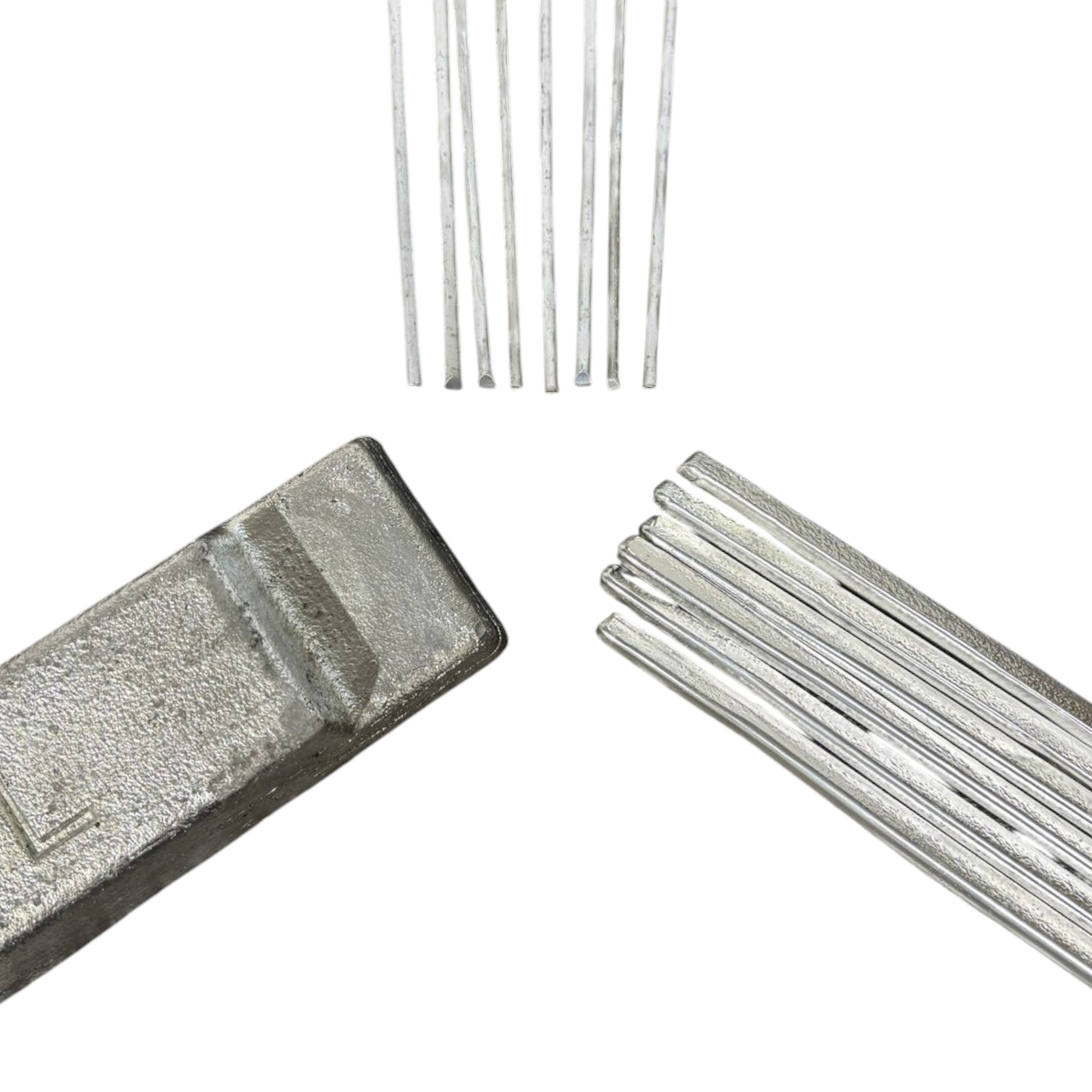

Packaging and Supply

Available in bars, chunks, blowpipe solder, and tinman sticks, Grade G solder meets bespoke order requirements from small batch repairs to large production runs. Contact DKL Metals today to discuss your packaging preferences and volume needs for industrial solder alloys in the UK market.

Quality Commitment and Assurance

DKL Metals ensures every batch of Grade G solder meets stringent quality control standards, maintaining precise chemical composition and performance testing. Our ISO-compliant manufacturing process guarantees consistency and reliability for your critical soldering and repair applications.

Learn More!