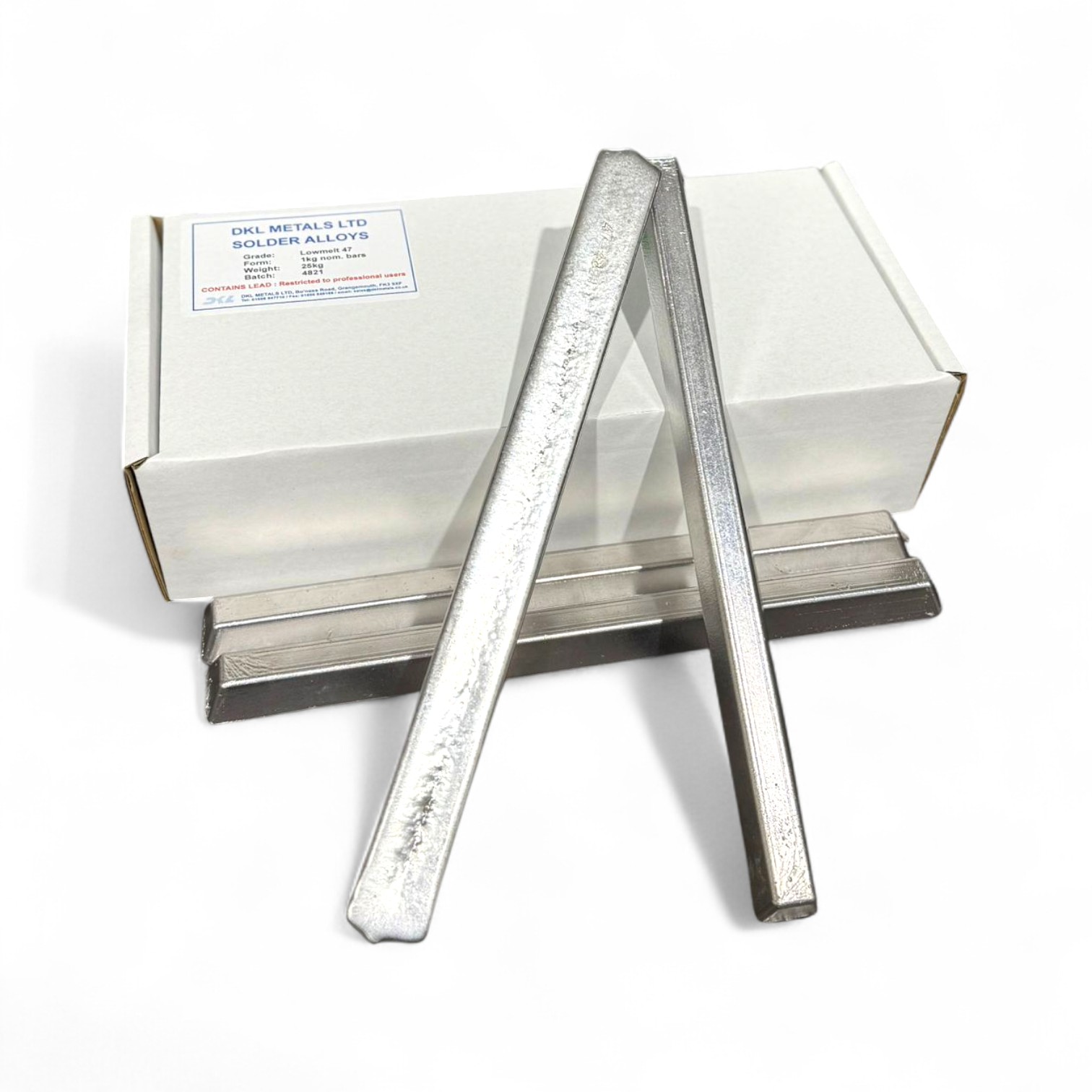

Low Melt Fusible Alloy 47

Precision Low-Temperature Alloy

Low melt Fusible Alloy 47 is a specially formulated low melting point alloy designed for precision casting and specialised applications requiring controlled melting temperatures. This fusible alloy offers superior flow characteristics and excellent cast detail at low pouring temperatures, making it ideal for use in investment casting, prototype models, and delicate moulding processes. This alloy sometimes is also known by the name Cerrolow 117.

Technical Data & Properties

| Property | Value |

|---|---|

| Solidus | 47°C (approx.) |

| Liquidus | 60°C (approx.) |

| Density | 8.4 g/cc (approx.) |

| Recommended Pouring Temperature | 50 – 70°C |

| Alloy Type | Low melting fusible alloy |

| Main Application | Investment casting, model making, precision low-temp applications |

Click Link Below for temperature conversion

Temperature Conversion Calculator | Basic Calculator

Key Benefits

- Very low melting temperature allows delicate moulds and materials

- Excellent fluidity ensures detailed mould filling

- Rapid solidification reduces cycle times

- Suitable for investment casting and prototype manufacturing

- Safe handling temperature enhances operator safety

Typical Applications

- Investment casting of small, intricate parts

- Model making and prototype development

- Specialist electrical and thermal applications

- Lost wax and precision moulding processes

Why Choose DKL Metals’ Low Melt Fusible Alloy 47?

DKL Metals provides Low melt Fusible Alloy 47 with precise composition control and consistent melting characteristics. Our UK-based supply ensures responsive delivery and expert technical support to help you achieve reliable casting quality and process efficiency for your specialist low-temperature applications.

Learn More!

DKL Metals – Understanding High and Low Melting Point Alloys